About Torchwood Enterprises, LLC

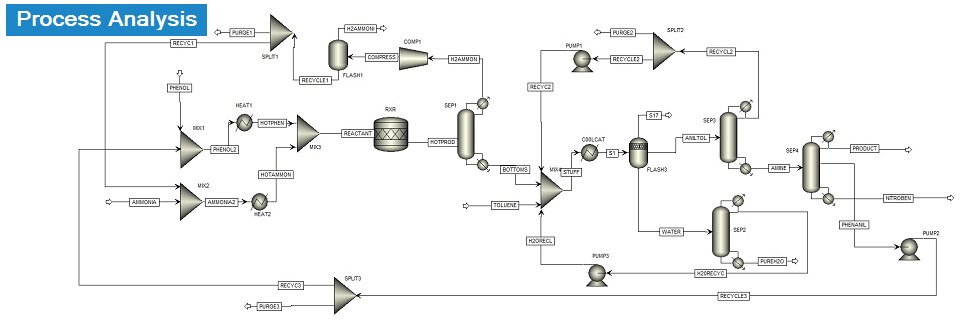

Torchwood Enterprises was established by Dr. John Prindle to assist chemical companies in the development and optimization of new and existing processes. From the beginning, the objective has been to provide useful insight and understanding into the behavior of integrated processes through the application of process analysis.

Consulting Services

Associates for Torchwood Enterprises have provided process analysis services for Argonne National Laboratory, Fortune 500 companies, and smaller process technology development companies. Services have included the following:

• Process Model Construction for an Existing Process with Validation through Comparison with Current Operating Data

• Process Model Construction for a New Process (Pilot Plant-Scale or Commercial-Scale) using Laboratory Data

• Applying the Validated Process Model for "What-If" Case Studies

• Applying the Validated Process Model to Identify Feasible Optimal Operating Regions

• Applying the Model for a New Process (Pilot Plant-Scale) to Shorten Process Development Time

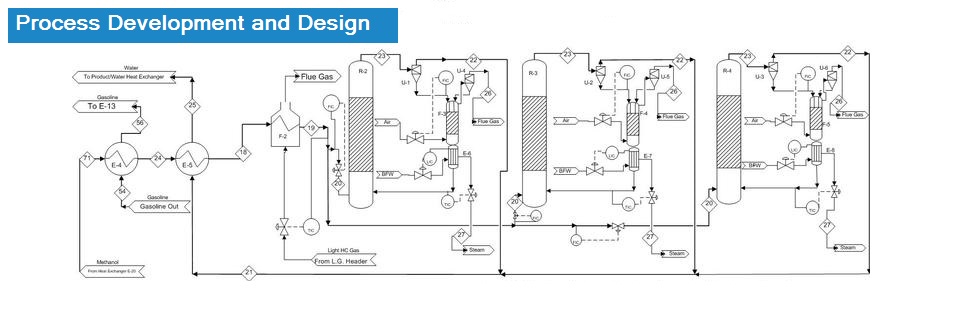

Leverage Our Skills to Shorten Your Time to Commercialization

Associates at Torchwood Enterprises have currently developed process models and used them to identify optimal operating regions for the following commercial processes:

• Acrylic Acid from the Oxidation of Propylene • Aniline from the Vapor-Phase Ammonolysis of Phenol • Phenol and Acetone from the Air Oxidation of Cumene • Acetic Acid from Methanol and Synthesis Gas (SynGas) • Acrylonitrile from the Vapor-Phase Ammoxidation of Propylene • Acrylonitrile from the Vapor-Phase Ammoxidation of Propane • 2-Ethyl Hexanol from Propylene and Synthesis Gas (SynGas) • 1,4-Butanediol from Propylene Oxide, Syngas, and Hydrogen • Styrene from Ethylene and Benzene • Cumene from Proylene and Benzene • Methyl Methacrylate from Methanol, Hydrogen Cyanide, and Acetone • Methyl Methacrylate from Methanol, Isobutane, and Oxygen • Ethylene Oxide from Ethylene and Oxygen • Ethylene Glycols from Ethylene Oxide and Water • Ethanol Amines from Ethylene Oxide and Ethanol • Toluene Diisocyanates (TDI) from 2,6-Dinitrotoluene, Hydrogen, Chlorine, and Carbon Monoxide • Several Other Novel Proprietary Processes

Construction of these detailed models is based upon literature or proprietary reaction models for both the desired and undesired reactions as well as process patents describing specific aspects of each process. For all of these process models, several process patents were used to develop a complete picture of both the reaction and separation sections.